I moved to the Phoenix valley in the fall of 2015, and went to TechShop because a relative said they thought they heard I might be able to learn how to weld there. Maybe they had a woodshop I could use, not sure.

I walked in the door and was immediately greeted by friendly people and shelves of cool projects that had been made there, and I was offered a tour.

I’m not sure if it was strategic, but the first things you see when you go on the tour are the laser cutters and the 3D printers. They had my money within 30 seconds. I was ready to sign the membership form right then and there, but that obviously wasn’t the end of the tour.

There was a huge communal work area. Nice big tables for me to use. A bank of computers full of every piece of design software you could need. A sewing section with CNC embroidery machines, industrial sewing and serger machines, and a CNC quilter. What?!

There definitely was a wood shop which, in addition to the standard equipment and a finger-saving SawStop table saw, included two CNC wood mills. Seriously, when can I start?!

Outside of the wood shop there is an injection molding machine and a vacuum former. I didn’t have a clue what I would do with a vacuum former, but as with many tools there, once I took the basic safety and usage class, I had ideas tumbling out of my head. I made my first vacuum formed piece less than an hour after the class ended.

The next room on the tour housed the metal shop, with a couple of metal mills, a CNC mill, and a lathe. Next to that is the rest of the metal shop, with several welding bays (“yes, you can learn to weld here, that’s the idea!”), saws, and other sheet metal tools. Wedged between those rooms is a space for spray painting and a walk-in size powdercoating oven.

Out back, past the blacksmithing forges (cool!), is a massive waterjet that can cut through very thick steel, stone, and concrete up to several inches thick. Here’s my money, gimme my membership badge, this is amazing, let’s get going!

And that’s all just the “stuff”. Flowing throughout all of it were dozens of people making their projects. Making incredible things. Running their businesses, creating their art, finishing their school projects, just making for the joy of making.

They are nice and friendly people, of course, but also so so helpful. Everybody shared information and advice, and everyone had something to offer. Even though I only learned the lasers relatively recently, in my enthusiasm I learned quite a bit about how to do things with them, and could help out others in a modest way.

Many of the folks at TechShop were true craftspeople, though. One man was building a working steam engine replica, large enough for him to ride on, from scratch, in the metal shop. One woman welds scrap metal into wonderful birds and bells. Another man made beautiful guitars from various fine woods and other materials. One guy seems to know how to use every single device in the building as if he made each one himself. The list goes on. Practically every day I’d see somebody making something amazing and fascinating (and once or twice that person might have been me).

My apartment – and my car – gradually filled up with things I made at TechShop. (I replaced my entire back seat with shelving I made in the woodshop, so I have more room for my camping and photo gear.)

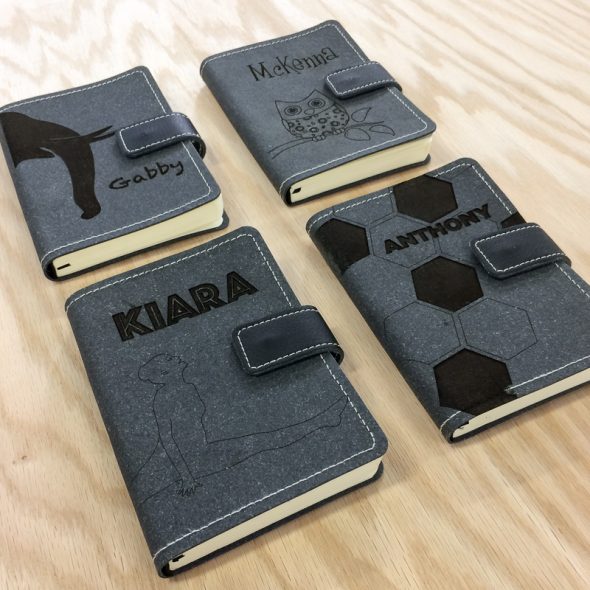

Friends and relatives got TechShop-produced gifts for several Christmases. Customers ordered products from me that I made at TechShop – using skills I didn’t even have when I took that tour two years ago.

After my initial fascination with the laser cutters and the CNC wood mills, I did finally learn how to weld. I took other metalworking classes, learned the waterjet, discovered a bizarre love for the serger, went from learning how to screenprint to selling a short run of my own custom t-shirts, did some moldmaking and blacksmithing and powdercoating, and…the list goes on.

Over the two years I was there I shifted my mentality from “if I need something, buy it” to “if I need something, can I make it?”, and throwing something away because it broke now became a challenge to learn how to repair instead. Making something as simple as a soap dish (yes, my shower has a graceful aluminum soap dish in it, powdercoated, of course) forces you think about how to design something that has both good function and a nice form, and that’s a different way to think.

Here are just a few of my projects that I made at and because of TechShop:

- Screenprinting t-shirts

- Reclaimed wood beam and steel bench

- Steel i-beam and reclaimed wood coffee table

- Recessed lens board and flat lens boards

- Reclaimed wood and steel end table

- Custom ground glass protective covers

- Portable darkroom!

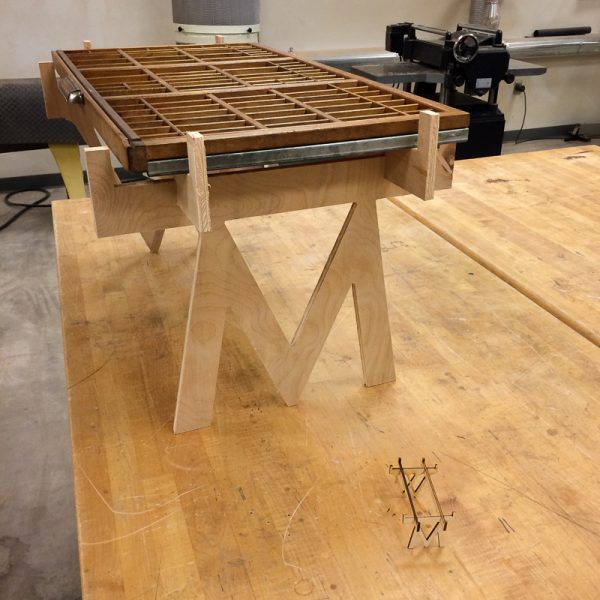

- Typesetting drawer coffee table

- Various other projects

And a thread that runs through all of this is the staff. They are all so friendly and helpful. It was clear from the instant I first walked in the door that they wanted me there, even with no skills and tons of questions to pester them with. They know so much. They all do their own things, too, so they are deeply familiar with the equipment, but also agile in brainstorming and troubleshooting. Because of the staff there, absolutely nothing was intimidating (other than the fact that all of the staff seemed to be half my age and twice as accomplished). I’d list them, but I’d miss one by accident – there are so many wonderful people at TechShop.

TechShop abruptly closed and declared Chapter 7 bankruptcy yesterday. I feel like I learn something new every time I work at TechShop, and yesterday was no different: I learned that while no bankruptcy is good, this type is particularly not good, as it does not allow them to restructure and continue operating in the mean time. TechShop was over, immediately and absolutely, with a trustee already picking over the remains. I felt, and I don’t say this lightly, considering my life over the past couple of years, as if I had lost somebody close to me.

My fiancee and I only moved to the Phoenix area so she could go to grad school at ASU. We didn’t plan on staying any longer than her three-year program. But I came to really like living here, for a couple of reasons. One was the access to the southwest – I love it out here – but the same could be true of pretty much any home in a triangle from Santa Fe to Los Angeles to Seattle.

What made this a good spot for me was TechShop. It was a major factor in us deciding to stay here a bit longer, after grad school. We even considered moving south a little bit, since the only unique thing that I go to is TechShop, in Chandler (grocery stores and gas stations are ubiquitous) and Kari teaches some at Chandler-Gilbert Community College. We have friends and relatives in the Chandler area. We considered moving there because of TechShop, which would have brought our meager expenditures to Chandler’s economy.

More than we already did. I spent a couple thousand dollars at TechShop. I took breaks to eat meals at the San Tan Brewery, Serrano’s, and other restaurants around TechShop in Chandler. I bought supplies at the Home Depot, Lowe’s, Port Plastics, and other suppliers in Chandler. TechShop brought intelligent, creative, productive people – and their money – to Chandler and its economy.

TechShop was a place that was very important to me. It exercised my brain, and allowed me to make things I need, both practically and mentally. But students lost a place to work on school projects, some of which are due in the coming weeks. Businesspeople lost their livelihoods – the guitar maker was in the middle of a commission, just to name one. And that fantastic staff, my friends, lost their jobs.

Fortunately, all of these people make stuff, and within hours of finding out the horrible news, some of them started making plans for this particular phoenix to regenerate. While I’m still stuck in anger and depression, with a bit of denial thrown in, some very competent people have moved past acceptance and are working hard with officials in the Chandler government and at Arizona State University, as well as other maker spaces in the valley, to figure out what’s next. I hope we get something worked out soon – I have stuff to make.

Hi Mark. Very impressed with this plAce and your experiences. I have thought for a long time that you can do lots with your ingenious approach to projects. Beautiful table, highly creative t shirt, fun “toys” to play with. Ruth